Feature:

- The work efficiency is about 1.5 faster than single hose pipe and is applicable to viscous spray drying.

- Fluid Bed Spray Granulator / Dryer (Dual Hose Pipe) is widely used in chemical, food and pharmaceutical, for the powder and spray granulate and drying of the Powder, Particle.

- Follow the regulation of cGMP, PIC/S, GMP.

- It’s a multifunctional machine that works for powder particle drying, powder granulating, micro-pellet granulation, micro-pellet film coating.

- The hot air source undergoes preliminary filtering, intermediary filtering and then high-efficiency filtering to thoroughly clean the inlet air source.

- The temperature can be divided into high-temperature drying or low-temperature dehumidifying system and therefore becomes low-temperature drying.

- The drying efficiency is 10~20 times greater than the general oven.

- Air volume control using proportional automatic damper control.

- The control system adopts PLC automated control that can be operated via man-machine interface and read all temperature parameters, or convert files to print the temperature parameters.

Optional:

- Explosion proof system. (If organic solvent is used)

- The de-humidify device of the air inlet system.

- The air inlet system adopts the cold and hot air to mix together which controlled by PID, the temperature is responded rapidly and accurately.

- Air volume control using proportional automatic damper control.

- WIP system.

- Vacuum feeding and discharge device.

- Dust collector system.

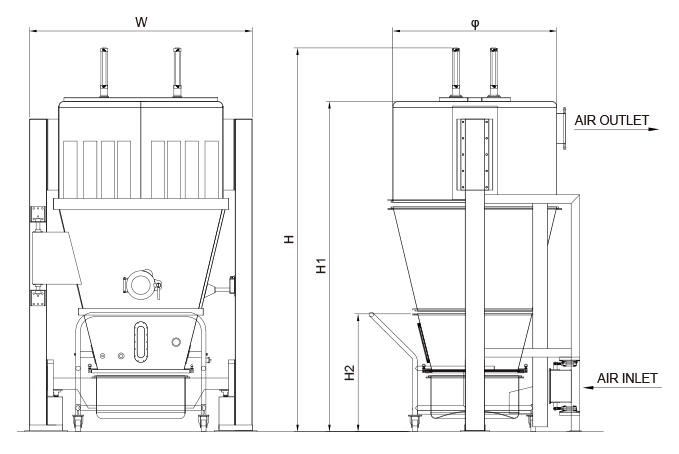

Container

Tilting device:facilitate the operator pouring out and cleaning.

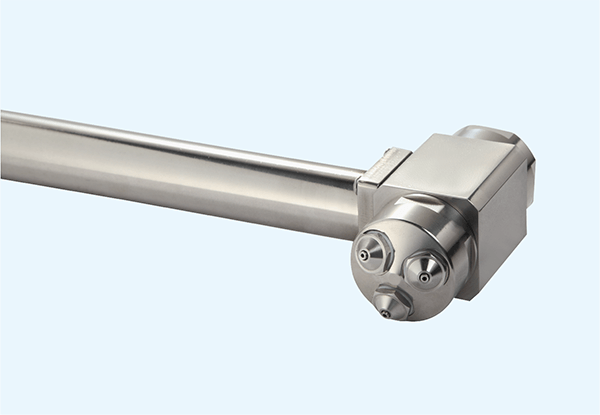

Spray Gun

Three spray nozzles:in the event of blocking, liquid can through the other two nozzles and will not immediately affect the product.Line Graph:

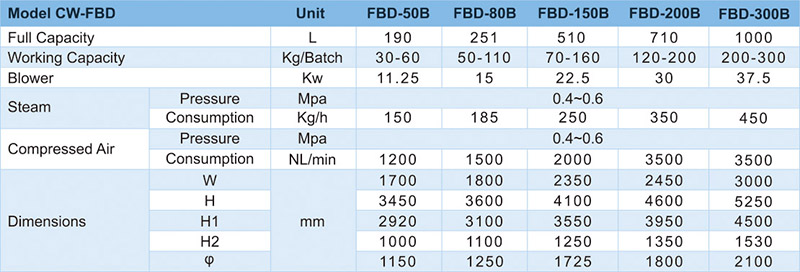

Specification:

Video: